Research and Competitions

New Construction

In Progress

Revitalization

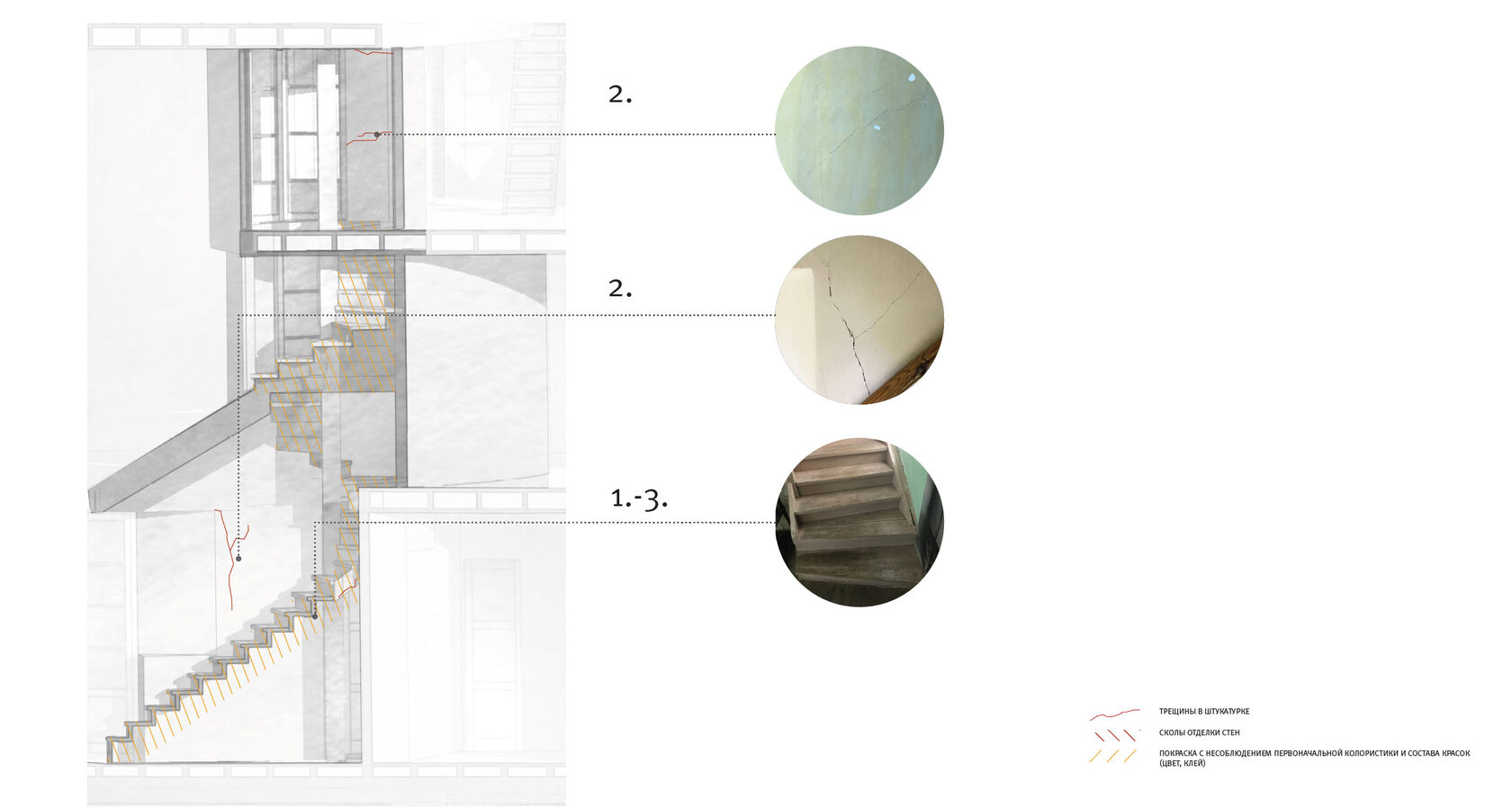

- Loss of adhesion of the tetitva to the wall, which is manifested in cracks of the finish

- Cracks in the plaster finish of the wooden walls and partitions of the staircase cylinder, the adhesion of the plaster finish with the base has been lost to a significant degree.

- Physical deterioration of the stair treads. Mainly concerns the treads. Reduction of cross-section in the treads (up to 8 8 mm loss of cross-section), localized jamming, creaking and deformation of the treads under load during walking.

Genetic defects associated with experimental nature of the structural solutions of the house:

In protocol of the field commission noted poor quality of painting of staircases.

28.03.1929

Made a drawing of a spiral staircase.

Отрывные календари с записями, относящимися к строительству и эксплуатации дома. Архив дм. (1929 г.)

History of construction

1941-1945

In July 1941, an airplane bomb hit the building of the Vakhtangov Theater, blowing out the glazing of the Melnikov house. Only the basement, into which the family moved, remained in operation. The rest of the rooms were not heated, the openings were filled with improvised materials due to the lack of funds. The constructions of the house suffered from dampness. It is possible to assume that it was in this period that the process of rotting of wooden ceilings on supports and the growth of deflections started.

ООО «ИнжсСтройСервис — 1». М., 2018 г.: обследование несущих и ограждающих конструкций. Том 1; стр. 46.

1982

The preliminary survey of the year indicated creaking and sagging stair treads.

ООО «ИнжсСтройСервис — 1». М., 2018 г.: обследование несущих и ограждающих конструкций. Том 1; стр 55.

1984

There are oblique cracks on the partition enclosing the interfloor staircase.

1996-1997

Restoration of a spiral staircase.

Fragmentary restoration of stairs with inserts and compounds, fixing them with adhesive compositions. Restoration of the plaster layer, expansion and patching of cracks, strengthening of weak fragments with screws on the solution. Painting. Scraping of the metal casing of the supporting post, strengthening and cleaning of the handrail.

Fragmentary restoration of stairs with inserts and compounds, fixing them with adhesive compositions. Restoration of the plaster layer, expansion and patching of cracks, strengthening of weak fragments with screws on the solution. Painting. Scraping of the metal casing of the supporting post, strengthening and cleaning of the handrail.

2002

From the technical report it can be noted that in the living room and on the staircase the condition of the finish was found to be satisfactory.

1999

2013

Техническое заключение о состоянии строительных конструкций и штукатурки стен и потолков в помещениях памятника архитектуры «Жилой дом-мастерская архитектора К. С. Мельникова» по адресу: г. Москва, кривоарбатский пер., дом 10. Проектно-сметное бюро комитета по культуре москвы; 2002 г.

2018

The stairs of the building are currently in limited serviceable condition. The bearing capacity of the building column is ensured. The staircase between floors is subjected to the most intensive loads. Therefore, it has a significant physical deterioration a lot of cracks in the plaster layers, when tapping the plaster layer in some places "bounces", paint layers have mechanical damage. The steps squeak when walking, they are erased in the entry points. The stiffness of steps and handrails is insufficient. The opening revealed that the wood was significantly dried out (including due to heat leakage from heat ducts), there were various pads made of slivers under the steps, the lower surface of the opened step was glued with a polymer resin mesh. The ceilings of the 1st and 2nd floors transmit the load to the staircase partitions, which results in multiple vertical, inclined and horizontal cracks.

Defects: Inter-floor stairs

ООО «ИнжсСтройСервис — 1». М., 2018 г.: обследование несущих и ограждающих конструкций. Том 1; стр 163−165.

Научно-технический отчет «проведение геотехнического мониторинга здания по адресу: г. Москва, Кривоарбатский пер., д. 10» за период ноября 2012 г. По январь 2013 г. НИИ ОСП им. Н. М. Герсеванова; м., 2013 г.

ООО «ИнжсСтройСервис — 1». М., 2018 г.: обследование несущих и ограждающих конструкций. Том 1; стр 48.

ООО «ИнжсСтройСервис — 1». М., 2018 г.: обследование несущих и ограждающих конструкций. Том 1; стр 47.

Протокол совещания выездной комиссии по вопросу выполнения ремонтно-реставрационных работ по памятнику архитектуры «Жилой дом-мастерская архитектора К. С. Мельникова»; 11.06.1999 г.

There are multiple vertical, inclined and horizontal cracks in the plaster layer of the partition walls enclosing the staircase with the opening from hair cracks to 2,5 2,5 mm.

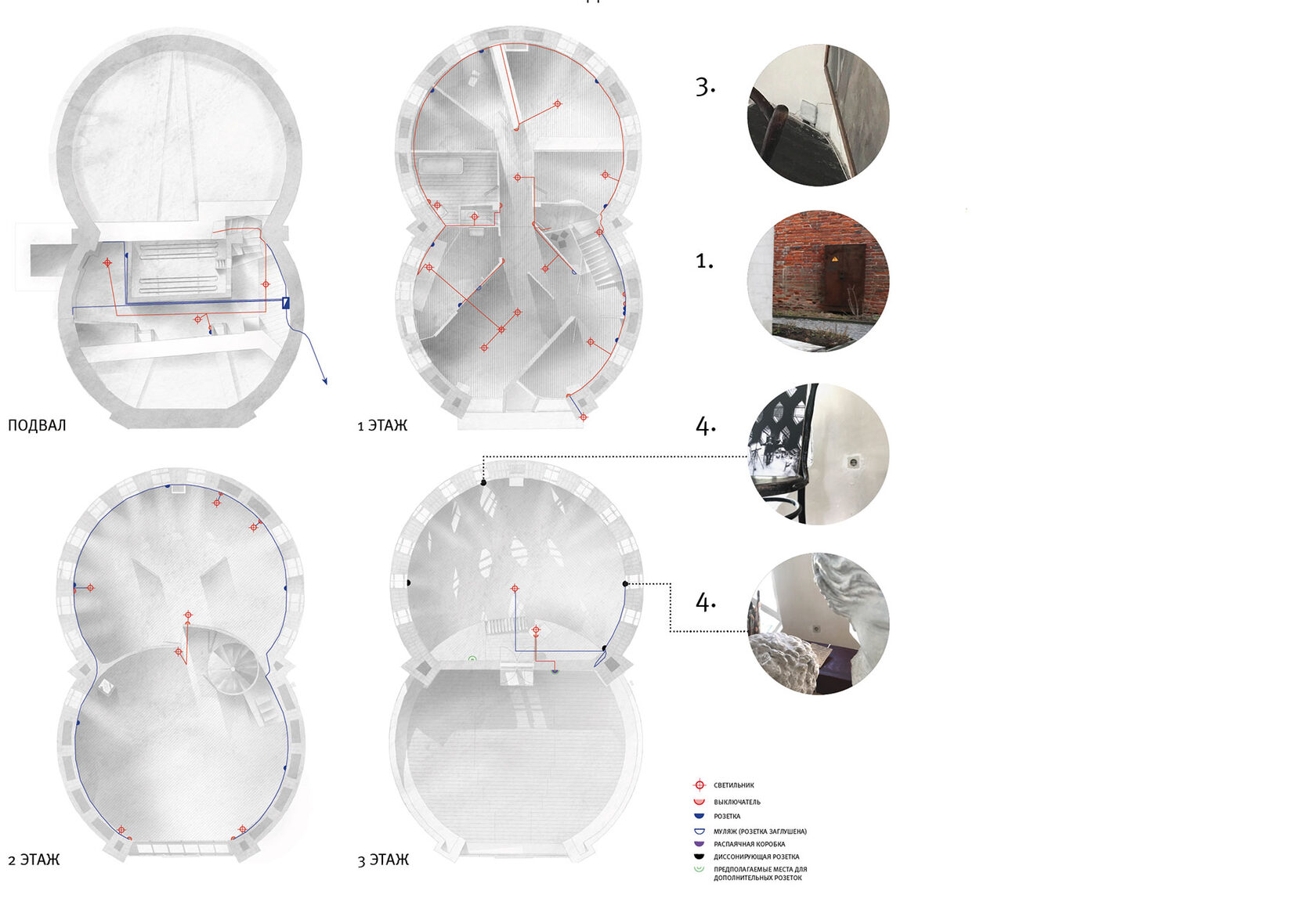

- The existing power supply on the wall on the eastern boundary of the site does not meet the current requirements and regulations for electrical installations;

- By today there is no scientific and design documentation, including the territory of improvement and actual power supply and electrical lighting of the object;

- No electrical outlets in spring partition of the 3rd floor workshop on the antresol;

- The sockets and junction boxes installed in the 1990s on the 3rd floor of the workshop in place of the original built-in ones do not match the aesthetics of the house and spoil the visual appearance of the interiors.

Electrical equipment and electrical lighting:

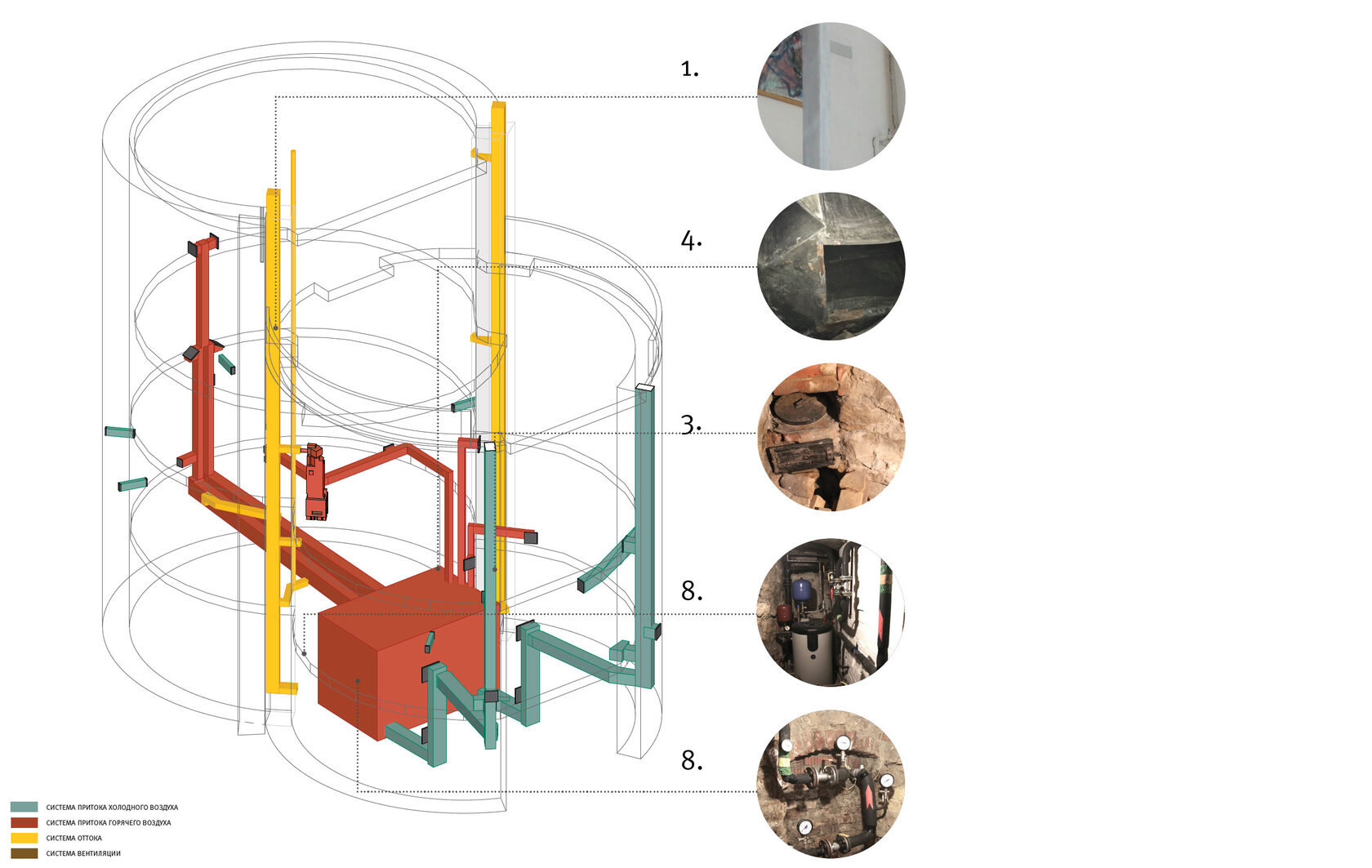

Heating and Ventilation:

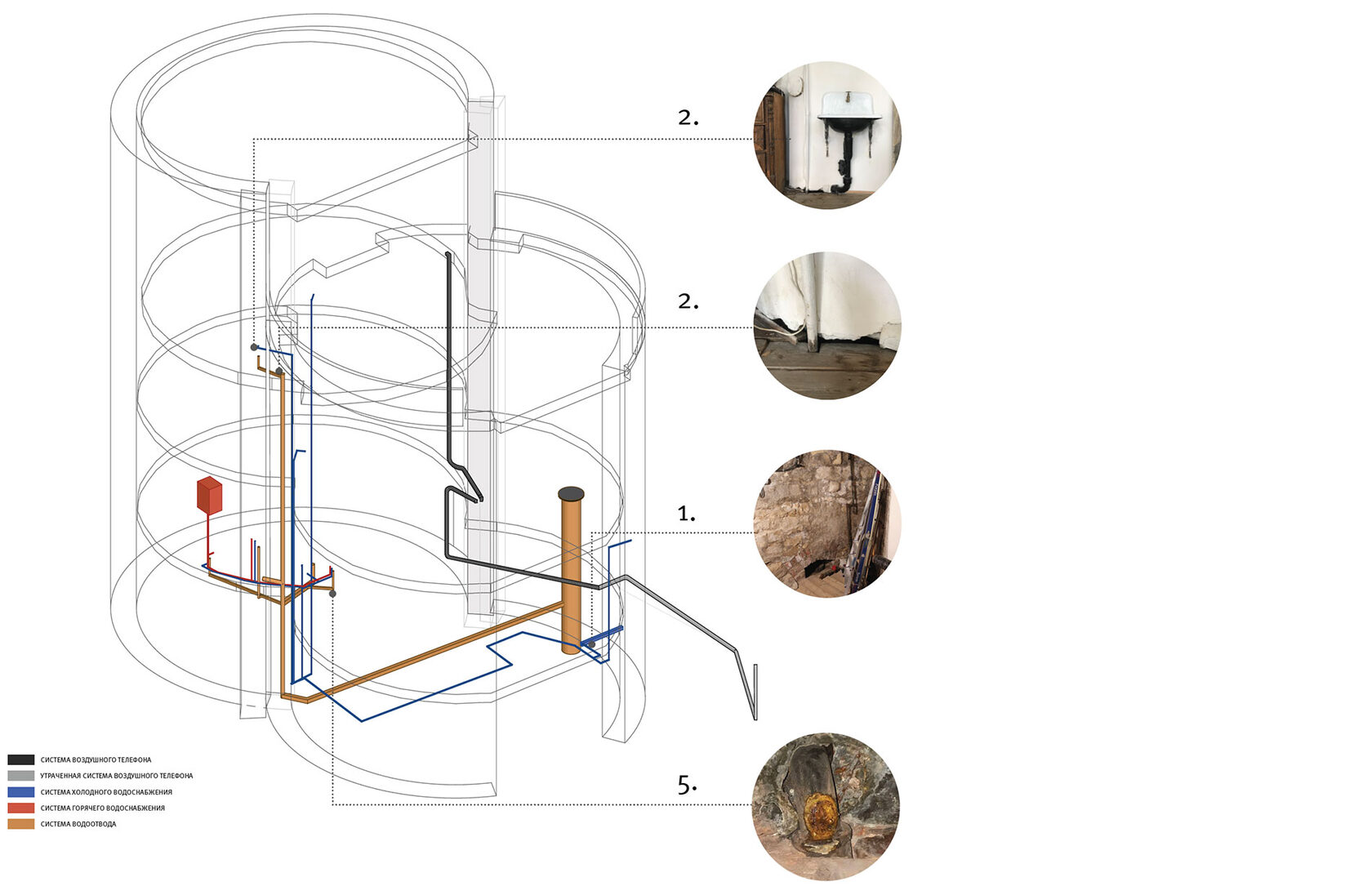

Water supply and wastewater disposal:

- It is assumed that there is a horizontal outlet from the west exhaust duct in the 3rd floor workshop; further inspection is required.

- Some sections of the supply ducts to the calorifier chamber were severely corroded from the street side

- Existing air heating ventilation systems are becoming progressively clogged; regular monitoring and cleaning is required.

- Due to the dependence of natural ventilation and air heating on outdoor air parameters and air heater (register) temperatures, an operating manual is required;

- The existing air heating and ventilation system does not provide the required relative humidity in the cold season;

- Measures are required to humidify the supply air.

Cold water supply:

- Wear and tear of the cold water supply system by 40%;

- Breaks and corrosion on standpipes going to third floor

- Wear and tear of the DHW system is 30%

Hot water supply:

- The deterioration of the water drainage system is 75%

Drainage:

Weaknesses:

- Existing communication and alarm systems need to be upgraded for fire safety reasons.

Started base I and II strokes of the heater

10.03.1928

M.V. Gusev purchased material on canalization.

Engineering Chronology

27.11.1928

Repin is at the construction site again.

The carpenters finished lining the floor of the studio was in considering the water supply to the meter was in considering the sewerage at Y.Y. Zvyagintsev’s place

The carpenters finished lining the floor of the studio was in considering the water supply to the meter was in considering the sewerage at Y.Y. Zvyagintsev’s place

28.11.1928

I gave Aksenov a sketch for the heater boxes.

I met with Mr. Shovsky and they showed me the lease agreement.

I met with Mr. Shovsky and they showed me the lease agreement.

29.11.1928

I spent the whole day with the bakers

There was M. V. and Repin and no help.

There was M. V. and Repin and no help.

30.11.1928

Together with Lev Pavlovich, the two of us broke down the heater and then the stovemen began to lay it.

15.12.1928

Finally got the power back on

1125 red bricks have been delivered.

The calorifier is finished and I’m heating it.

Good.

1125 red bricks have been delivered.

The calorifier is finished and I’m heating it.

Good.

04.12.1928

17.01.1930

2018

The tracing of the lost line of the air telephone system from the basement under the ground to the tile was investigated. A preserved section of the line was found under the eastern lawn.

Протоколу совещания выездной комиссии по вопросу выполнения ремонтно-реставрационных работ по памятнику архитектуры «Жилой дом-мастерская архитектора К.С. Мельникова» 11.06.1999 г.

Defects: Engineering networks

We've started phone entry

19.01.1930

The phone works

19.05.1930

Well?!

I started up the heater, all day long it was overturned.

Only by night (morning) it melted.

I started up the heater, all day long it was overturned.

Only by night (morning) it melted.

16.08.1934

We punched two holes in the channels for inflow.

1941-1945

The most difficult period for the building, connected with significant losses and alterations of the original author’s solutions, was the winter of 1941−1942. The whole family is forced to live in the basement. In order to keep the house warm, K.S. Melnikov built temporary stoves. Later, a new stove was built in place of the collapsed stove in the living room, which has survived to the present time. The temporary stoves also worked on the other floors, but this was not enough — the house gained moisture and rotting began.

1957

According to the 1957 project, the water heating pipes were installed from the west neighboring section in a brick non-passable duct running along the west façade of the building at a distance of about 2 meters. The pipe inlet is through a former coal hatch in the basement.

1958

In 1958 the house was connected to the central water heating system, steel registers were installed in the calorifier chamber.

1996-1997

After dismantling the scaffolding around the building and removing the underlying slabs, the backfill sand and part of the soil affected by the antiseptic washed off from the forests were removed. The fence of the site was recreated, its layout and landscaping were carried out. Hot water supply pipes, power cables to houses, and telephone network cables were re-laid. The perimeter of the building is covered with a concrete screed with a cement leveling screed, and the eastern drainage channel is restored.

1999

It is required to carry out all external and internal works on engineering support of the monument with submission to operation, to restore the heating station according to the old scheme without installation of automatics and transit heat pipelines beyond the site boundaries according to

2002

The transit heating line has been moved to a bypass on the north side of the site. The previously existing transit line is disconnected.

Отрывные календари с записями, относящимися к строительству и эксплуатации дома. Архив Д М. (1928 г.)

Отрывные календари с записями, относящимися к строительству и эксплуатации дома. Архив Д М. (1930 г.)

Отрывные календари с записями, относящимися к строительству и эксплуатации дома. Архив Д М. (1934г.)

Т. В. Царева. Комплексные исследования объекта культурного наследия федерального значения «экспериментальный жилой дом, 1927−1929 гг., арх. Мельников К. С.». Историко-культурный раздел. Москва 2018, стр 73.

Technological recommendations for plastering and painting compositions

- Ecolimy K+ premix produced by BestTradeCenter LLC is a composition based on air hydrated lime and Portland cement modified with special additives.

- The system of ready dry mixes “BIRSS 43C5” - spray, ground, cover produced by JSC “Birss” - is a lime-cement plaster on the basis of hydrated lime. For plastering the basement part of facades and covered horizontal planes of the terrace parapet it is necessary to use mortars based on complex cement-lime mortar M75-100 (such as, for example, ready-made dry mixes “BIRSS 22T”, “BIRSS-15E”, “AXIL SHR-3 C-5”, premix “Ecolimy K Optima+”).

Technological recommendations for restoration and restoration of plaster finishing of facades and interiors:

Facade plastering compounds:

Lime-binding:

- Ready dry mix “ACCIL Resto ShR-1” produced by “Stalker ”Ltd. is a composition on the basis of hydraulic lime with a compressive strength of at least 4.0 MPa.

- Ecolimy K” premix produced by BestTradeCenter LLC is a composition based on air hydrated lime modified with special additives.

- The ready-made dry mixture “Runit” is classical, coarse and fine porous on lime binder.

Lime-binding with the addition of cement:

For plastering of facades we recommend compositions on lime binder, for plastering of plinth and horizontal planes we recommend compositions on complex lime binder. For plastering of a large cylinder sprengel partition on the third floor and interiors (plastering on the shingle), compositions based on complex lime-gypsum binder applied in the technique of improved or high-quality plastering are recommended. In case of thick plaster overlays on walls, as well as on protruding elements and joints of heterogeneous materials, reinforcing plaster polymer mesh with mesh size 40×40 mm should be used when applying plaster overlays thicker than 25 mm. Taking into account the composition and condition of the existing plaster finish, it is recommended to carry out plastering works with lime binder mortars in the form of ready mixes and premixes.

For painting of plaster facade finishes made on lime binder, lime coloring system in the form of ready paint should be used. These are: "Runit Izvestkovaya paint" St. Petersburg, "Histolith Innenkalk" by "Caparol", "Kieselit-Fassadenkalkfarbe" by Alligator factory (Germany). To strengthen the surface layer of old plaster it is necessary to use primers on the silicate base: "Runit Silicate Primer or Histolith Silikat-Fixativ. For painting the plaster surface of walls and ceilings made on lime-gypsum and lime binder it is necessary to use traditional reversible, previously used adhesive paints. Depending on the type of painting (simple, improved or high quality), from three to twelve operations of smoothing, priming, undercoating, sanding and filling of the plaster surface are performed. Glue paints are reversible, they can be removed with the help of water, but, together with them they are durable, if properly applied, they can last 10−15 years. The most durable are glue paints on casein binder. An important advantage of glue paints is their porosity: coatings made of these paints are air- and vapor-permeable and environmentally safe.

Ready-to-use adhesive paints are dry paint compositions that are diluted with water immediately before use. To improve the appearance and increase water resistance, it is possible to add olive oil (natural, combined or glyphthalic) to the paint. There are also dry semi-finished products, these are: "Painted whitewash", "Paint dry varnishes", "Decorative dry paints" made by domestic firms of paintwork manufacturers — paint factories of Moscow, Sergievo-Pasad, Yaroslavl, St. Petersburg. They consist of chalk and colorant. The glue solution is prepared separately and then mixed with the semi-finished product diluted in water.

Technological recommendations for the restoration and restoration of painted finish of facades and interiors:

Caparol (Germany) produces ‘Histolith Emulsionfarbe' paint, which is a product of further development and improvement of adhesive paints and contains a reversible mixture of binders, has increased resistance to contamination and biological damage. For painting wooden carpentry windows, stairs, in addition to domestic oil paints and professional (for wood) painting systems on polymer film-forming agent, Caparol painting systems based on linseed oil can be used. This is "Histolith Leinöefarbe" paint with high weather resistance. Untreated coniferous wood is first primed with Capalac Holz-Impägriergrund, then an intermediate and final coat of Histolith Leinöfarbe is applied.

For plastering interiors (as well as other surfaces on the shingle) it is recommended to use ready-made dry plastering mixes based on complex lime-gypsum binder. These are ready-made dry mixes "Birss-60IG", "Runit lime-gypsum", Aksil Resto SHR-IG. The mixtures are prepared on the basis of gypsum and lime, are characterized by high adhesive strength, low density, high porosity and plasticity, can be recommended for plastering walls and ceilings. Mark of mortars M40−50. Dry mix on the basis of gypsum and lime is characterized by low density and high porosity, mortars are technological and plastic, allow to keep constant humidity in the room.

Interior plastering compounds:

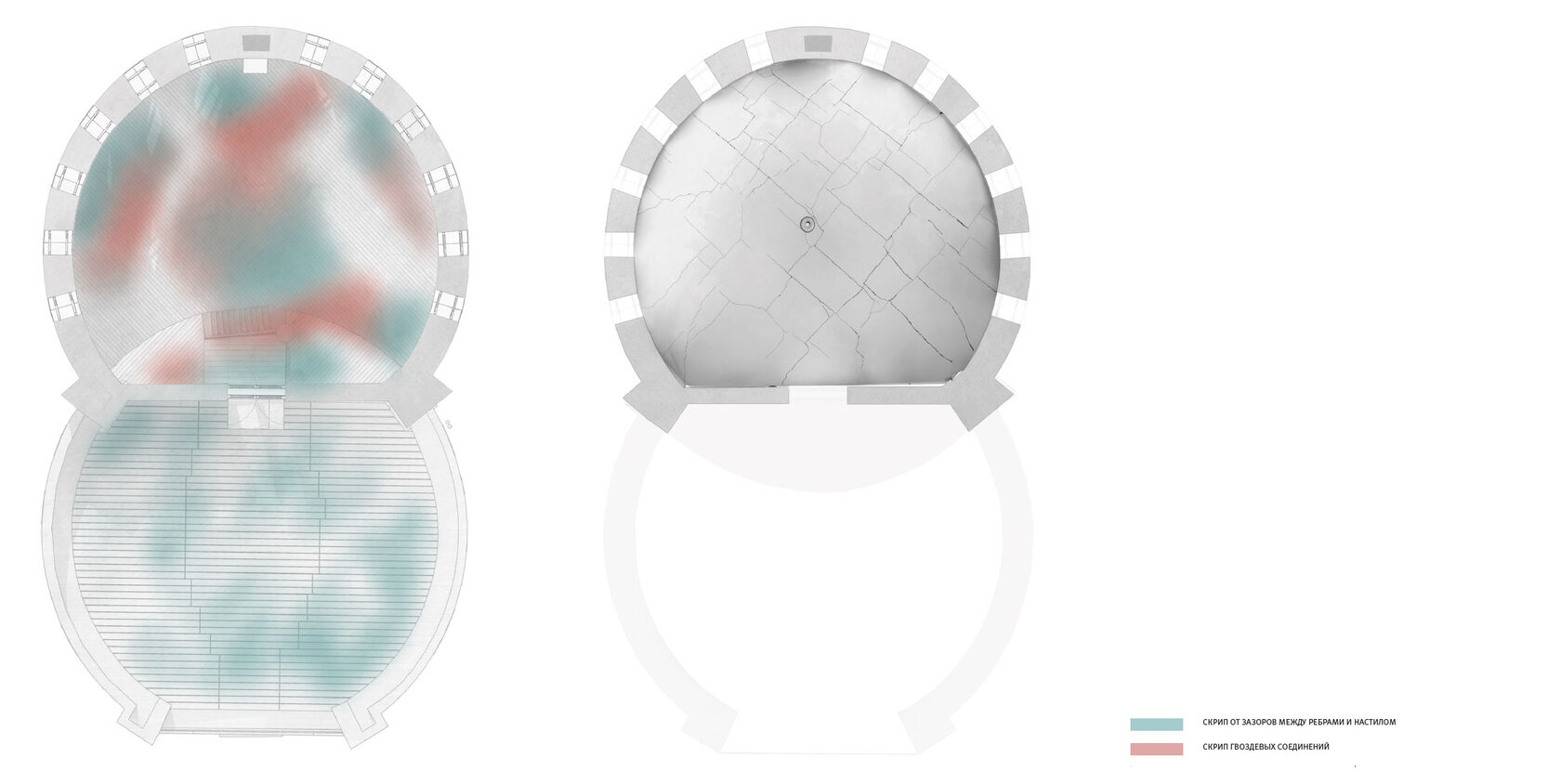

Defects: Interiors. 3rd floor: floors, ceilings

1. Plaster finish of wooden ceilings is cracked, cracks are multidirectional with up to 0.5-1.0 mm cracking

2. There are dynamic loads on the finishing layer of plaster ceilings due to the increase of the slab deflection under the influence of temporary loads.

3. There is a loose adherence of boards to the slab ribs, resulting in creaking, localized deflections in the workshop.

4. There is drying out of boards and out of tongue and groove joints

2. There are dynamic loads on the finishing layer of plaster ceilings due to the increase of the slab deflection under the influence of temporary loads.

3. There is a loose adherence of boards to the slab ribs, resulting in creaking, localized deflections in the workshop.

4. There is drying out of boards and out of tongue and groove joints

Mandatory Recommendations:

- Selective repair of defective areas of floors in the workshop;

- Covering of all plank floors with mastic according to the recommendations of the technical engineer.

Floors:

- Repair of plaster of the period of 1990s, elimination of cracks defects;

- Development of the section on safe operation of the facility

Ceilings:

Optional Recommendations:

- Painting of walls by research from archival sources and results of technological research 2018 year Glue paint by recommendation of the process engineer

Painting:

- Observations of dynamics of defects occurrence

Walls:

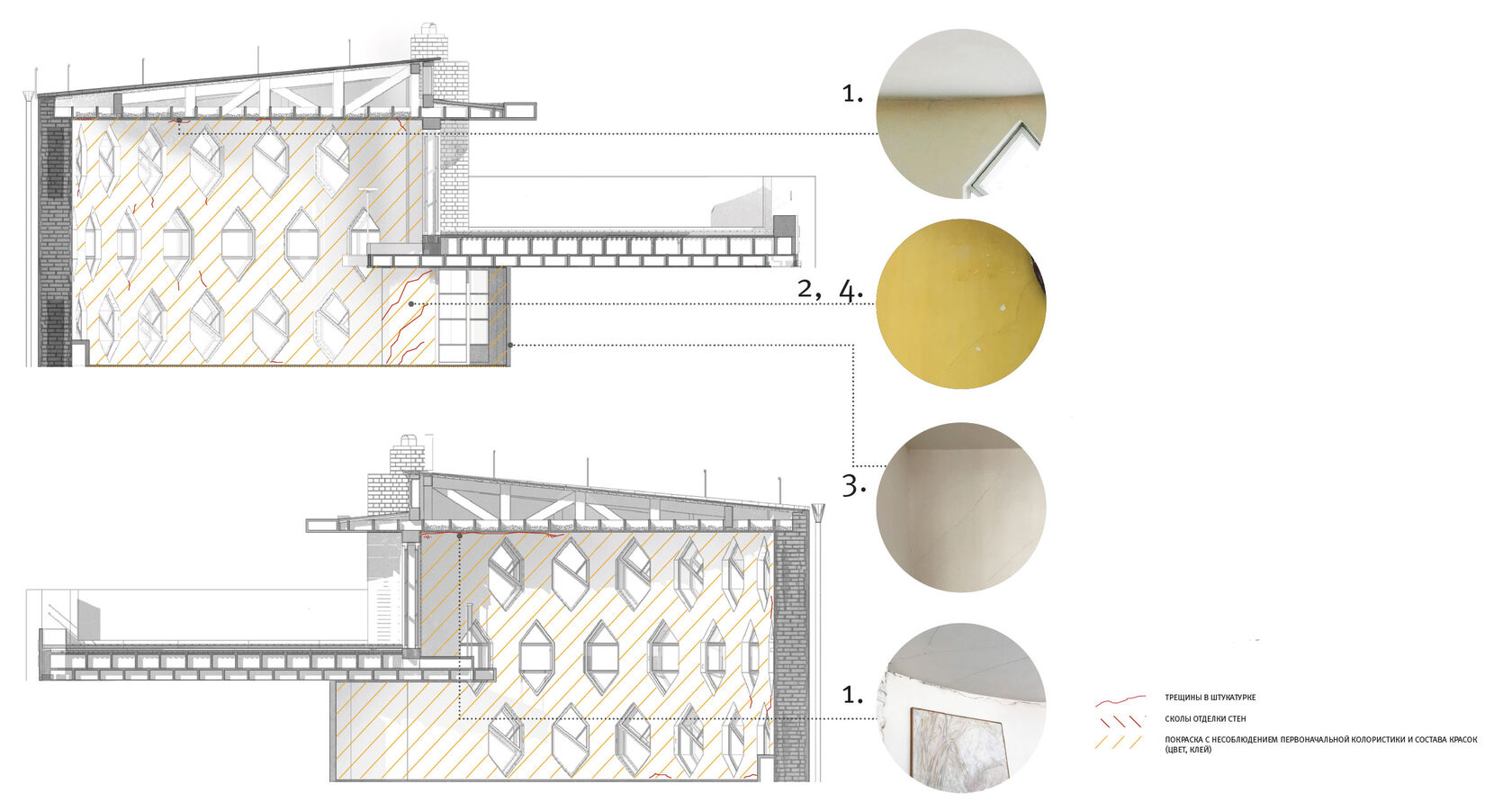

Defects: Interiors. 3rd floor: walls, ceilings

1. Cracks in the joints with the flooring along the entire perimeter of the workshop.

2. Wooden sprengel wall and stair cylinder wall have cracks in plaster layers at joints with slabs and shingles

3. Cracks in the plaster finish of the wooden walls-partitions of the staircase cylinder, the adhesion of the plaster finish with the base is lost to a significant degree.

4. During the restoration in the 1990s, the exterior of the staircase cylinder (yellow wall) was painted with the original coloring and paint composition of the 1930s.

5. The walls of the workshop are “whitewashed” (the effect of shoaling)

2. Wooden sprengel wall and stair cylinder wall have cracks in plaster layers at joints with slabs and shingles

3. Cracks in the plaster finish of the wooden walls-partitions of the staircase cylinder, the adhesion of the plaster finish with the base is lost to a significant degree.

4. During the restoration in the 1990s, the exterior of the staircase cylinder (yellow wall) was painted with the original coloring and paint composition of the 1930s.

5. The walls of the workshop are “whitewashed” (the effect of shoaling)

Mandatory Recommendations:

- Strengthening of finishing layers and crack repair, use of a special restoration compound according to the recommendations of a technical engineer.

Walls:

- Revision of the pre-roof after opening of the roof sheets;

- Existing slab deflection of the large and small cylinder slabs is maintained;

- Development of the safe operation section of the facility

Overlaps:

Read article

from the beginning

from the beginning

5

1. The existing external protective enclosure on the wall at the eastern boundary of the site does not meet current requirements and regulations for electrical installations;

2. There is no scientific and design documentation, including the adjacent territory and actual internal power supply and electrical lighting of the facility;

3. There are no electrical outlets on the 3rd floor ceiling;

4. The overhead sockets installed in the 1990s on the 3rd floor in the workshop in place of the original built-in sockets do not correspond to the aesthetics of the house and spoil the visual appearance of the interiors.

2. There is no scientific and design documentation, including the adjacent territory and actual internal power supply and electrical lighting of the facility;

3. There are no electrical outlets on the 3rd floor ceiling;

4. The overhead sockets installed in the 1990s on the 3rd floor in the workshop in place of the original built-in sockets do not correspond to the aesthetics of the house and spoil the visual appearance of the interiors.

- Provide for the replacement of the switchgear cabinet with a selection of options in the water supply unit on the wall on the eastern border of the territory;

- Carry out a generalized project of power supply and lighting on the territory and internal networks of the object;

- Provide additional electrical outlets in the mezzanine area and on the terrace for additional lighting of the 3rd floor workshop;

- To provide power supply to the floor panel of low-current systems in the basement, make the necessary changes in the electrical equipment section;

- Replacement of sockets in the workshop with sockets of the middle of the 20th century;

- Provide power supply to the drainage pump in the basement for emergency water drainage in case of leaks, in the area of the existing potato storage cellar.

Mandatory Recommendations:

Optional Recommendations:

Electrical equipment and electrical lighting:

1. Existing communication and signaling systems need to be updated for fire safety conditions

Low current systems:

Low current systems:

- Provide for an automatic fire alarm system

Defects: Engineering networks. Electrical equipment

- Provide for a burglar alarm system;

- Provide an access control system;

- Provide a warning and evacuation control system

Optional Recommendations:

- Repair of the plaster filling between the bowstring and the wall

- Repair and reinforcement of finishing layers

- Strengthening/restoration of steps between the 2nd and 3rd floors

Painting:

Mandatory Recommendations:

Defects: Inter-floor stairs

- Painting of walls according to research from archival sources and results of technological research 2018 year glue paints according to recommendation of the engineer-technologist

- Painting of steps by research from archival sources and by recommendation of the engineer-technologist

1. Cracks in plaster mortar in filling between the bowstring and the wall

2. Cracks in the plaster finish of the wooden partition walls of the stair cylinder, the adhesion of the plaster finish with the base is lost to a significant degree.

3. Physical deterioration of the stair treads. Mainly concerns the treads. Reduction of cross-section in the treads (up to 8 8 mm loss of cross-section), localized jams, creaks and deformation of the steps under load during walking.

4. During the restoration in the 1990s, the walls of the staircase cylinder were painted in accordance with the original coloring and paint composition of the 1930s

2. Cracks in the plaster finish of the wooden partition walls of the stair cylinder, the adhesion of the plaster finish with the base is lost to a significant degree.

3. Physical deterioration of the stair treads. Mainly concerns the treads. Reduction of cross-section in the treads (up to 8 8 mm loss of cross-section), localized jams, creaks and deformation of the steps under load during walking.

4. During the restoration in the 1990s, the walls of the staircase cylinder were painted in accordance with the original coloring and paint composition of the 1930s

- Given the irregular use of the drainage system, it is recommended to repair and replace individual elements: restoration of the wooden lining under the toilet, restoration and preservation of the sink in the kitchen;

- Cold welding, replacement of the elbow with corrosion and eakage in the calorifier chamber.

- The deterioration of the wastewater system is 75%;

- Corrosion and crack in the sewage pipe in the place where it passes through the calorifier chamber.

DHW:

Drainage:

Defects: Engineering networks. Water supply, water disposal

- Revision of shut-off valves is required on separate sections of the water supply in the kitchen and bathroom.

Drainage:

Water supply and wastewater disposal:

- Wear and tear of the cold water supply system by 40%;

- Breaks and corrosion on standpipes going to third floor

Cold water supply:

- Wear and tear of the DHW system is 30%

Hot water supply:

Mandatory Recommendations:

Cold water supply:

- Due to the concealed installation of the hvs pipelines to the third floor, we do not believe it is feasible to restore this System. Active intrusion into the subject walls will be required;

- Revision of shut-off valves on detached sections of the HTW in kitchen and bathroom is required;

- Painting of pipelines in the basement.

- Repair and painting of pipes in the basement, kitchen, and the living room

Melnikov House

2018 - until now. Russia, Moscow

- Survey, opening of the original ventilation duct (horizontal outlet) in the western part of the workshop, 3rd floor;

- Monitoring, cleaning and dusting of in-wall and attached air ducts, horizontal outlets, heating chamber walls;

- Replacement of supply and exhaust ducts in defective places;

- Provide for a system of heat-carrier regulation in the basement to minimize dependence on the mode of urban heat supply networks; to be developed on the basis of technical specifications of the Ministry of Energy;

- Develop a section of safe building operation on ventilation, heating and maintaining the required temperature and humidity regime;

- Grouting and treatment of the existing brickwork of the chimney on the left side of the staircase in the basement with stone reinforcement; cause moistening of the external walls of the basement.

1. It is assumed that there is a horizontal outlet from the west exhaust duct in the 3rd floor workshop room; further inspection is required.

2. Existing air heating ventilation systems are gradually clogging; regular monitoring and cleaning is required.

3. Damage and destruction of the brickwork of the chimney to the left of the staircase in the basement

4. parts of the supply ducts to the calorifier chamber and from the chamber to the north cylinder were badly corroded;

5. Due to the dependence of natural ventilation and air heating on the outdoor air parameters and the temperature of air heaters (registers), it is necessary to develop an operation manual;

6. The existing air heating and ventilation system does not provide the required value of relative humidity in the cold period of the year;

7. Measures for humidification of the supply air are required

2. Existing air heating ventilation systems are gradually clogging; regular monitoring and cleaning is required.

3. Damage and destruction of the brickwork of the chimney to the left of the staircase in the basement

4. parts of the supply ducts to the calorifier chamber and from the chamber to the north cylinder were badly corroded;

5. Due to the dependence of natural ventilation and air heating on the outdoor air parameters and the temperature of air heaters (registers), it is necessary to develop an operation manual;

6. The existing air heating and ventilation system does not provide the required value of relative humidity in the cold period of the year;

7. Measures for humidification of the supply air are required

Optional Recommendations:

Heating and Ventilation:

Defects: Engineering networks. Heating and ventilation

- Provide solutions for air humidification in the heat chamber during the cold season; to be developed according to a separate project.

Mandatory Recommendations:

Read article

from the beginning

from the beginning

5